Tension and shear are fundamental mechanical forces where tension pulls materials apart, while shear causes layers to slide against each other. Understanding the differences between tension and shear is crucial for analyzing structural integrity; discover more in this article.

Table of Comparison

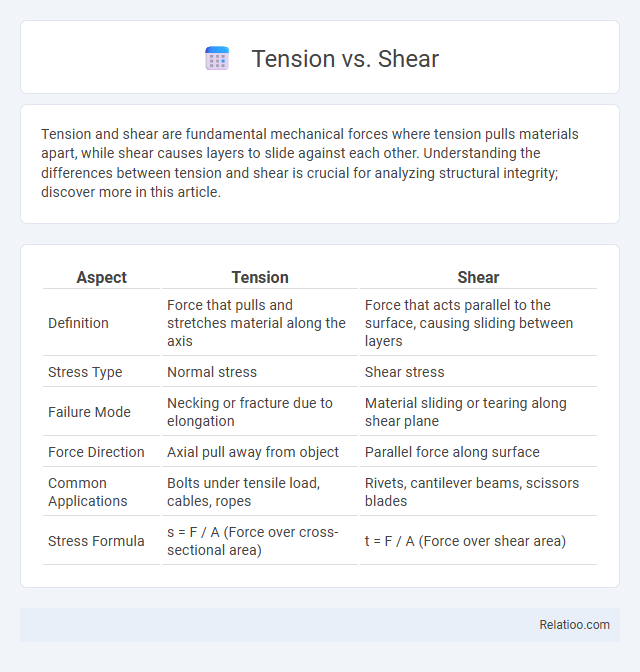

| Aspect | Tension | Shear |

|---|---|---|

| Definition | Force that pulls and stretches material along the axis | Force that acts parallel to the surface, causing sliding between layers |

| Stress Type | Normal stress | Shear stress |

| Failure Mode | Necking or fracture due to elongation | Material sliding or tearing along shear plane |

| Force Direction | Axial pull away from object | Parallel force along surface |

| Common Applications | Bolts under tensile load, cables, ropes | Rivets, cantilever beams, scissors blades |

| Stress Formula | s = F / A (Force over cross-sectional area) | t = F / A (Force over shear area) |

Understanding Tension and Shear Forces

Tension forces stretch materials by pulling them apart, while shear forces act parallel to a surface, causing layers to slide against each other. Understanding the difference between tension and shear is crucial in structural engineering for designing components that resist deformation and failure. Materials like steel and concrete exhibit different behaviors under these forces, with tension typically causing elongation and shear leading to shear strain or failure along a plane.

Fundamental Differences Between Tension and Shear

Tension and shear are fundamental types of stress that materials experience under different loading conditions; tension involves forces pulling apart materials along their length, creating elongation, while shear involves forces that cause layers to slide past each other, resulting in deformation parallel to the force direction. You must understand that tension stresses are axial and act normal to the cross-sectional area, whereas shear stresses are tangential and act parallel to the surface. Recognizing these fundamental differences helps optimize material selection and design for structural integrity in engineering applications.

Real-World Examples of Tension and Shear

Tension and shear forces play critical roles in structural engineering, with tension commonly seen in suspension bridge cables supporting loads along their length, and shear evident in riveted joints where forces cause layers to slide past one another. Elevator cables experience tension as they bear vertical loads, whereas bolts in machinery undergo shear stress due to lateral forces during operation. Understanding these distinct force types ensures proper material selection and design for safety in real-world applications like cranes, towers, and automotive components.

How Tension Works in Structural Materials

Tension in structural materials occurs when forces act to stretch or elongate the material, causing internal stress along its length. The material resists this by distributing load uniformly across its cross-section, maintaining stability and structural integrity under tensile stress. Understanding how tension works helps you design components that prevent failure due to stretching or cracking in critical areas.

The Mechanics of Shear Forces

Shear forces act parallel to the surface of a material, causing layers to slide against each other, contrasting with tension that pulls materials apart along their length. The mechanics of shear involve internal stress distribution where shear stress is maximized along specific planes, often leading to deformation or failure if the material's shear strength is exceeded. Understanding this behavior is crucial for designing structures that can endure combined tension and shear loads, ensuring your components maintain integrity under complex stress conditions.

Common Applications: Tension vs. Shear

Tension forces pull materials apart and are commonly seen in applications like cables, ropes, and structural beams in bridges, where materials must withstand stretching without failure. Shear forces act parallel to the surface and are critical in cutting tools, riveted joints, and bolted connections, ensuring components resist sliding or deformation along the plane. Understanding your material's response to tension versus shear helps optimize design and ensure safety in mechanical and structural engineering tasks.

Failure Modes: Tension vs. Shear Stress

Tension and shear stresses cause different failure modes in materials, with tension leading to brittle fracture by pulling the material apart, while shear stress results in sliding or deformation along a plane. Your structural components under tension are prone to crack propagation perpendicular to the applied force, whereas shear stress failure typically occurs along a diagonal plane due to material slippage. Understanding these distinct failure mechanisms helps optimize design for durability and safety under specific loading conditions.

Testing Methods for Tension and Shear

Testing methods for tension and shear focus on measuring material strength under different stress conditions. Tensile testing uses a universal testing machine to apply uniaxial force until the specimen fractures, capturing data on ultimate tensile strength and elongation. Shear testing employs fixtures like the double shear or single shear test setup to evaluate a material's resistance to forces that cause sliding failure along a plane. Your choice of testing method depends on the specific stress type your material or component will encounter in service.

Importance in Engineering Design

Tension, shear, and compression are fundamental forces considered in engineering design to ensure structural integrity and safety. Understanding the distribution and magnitude of these stresses allows engineers to select appropriate materials and design geometries that prevent failure under load. Your ability to accurately analyze tension, shear, and compression directly impacts the durability and performance of mechanical components and civil structures.

Choosing Between Tension and Shear Solutions

Choosing between tension and shear solutions depends on the specific load conditions and material characteristics of your project. Tension forces pull materials apart, requiring components with high tensile strength, while shear forces act parallel to the surface, demanding resistance to sliding failure. Understanding the direction and magnitude of applied forces ensures selection of the optimal solution to enhance structural integrity and durability.

Infographic: Tension vs Shear

relatioo.com

relatioo.com