Tension and bending are fundamental forces affecting relationship dynamics, where tension creates internal stress by pulling partners apart, while bending introduces flexibility and adaptation through external pressures. Explore how balancing tension and bending can strengthen bonds in this article.

Table of Comparison

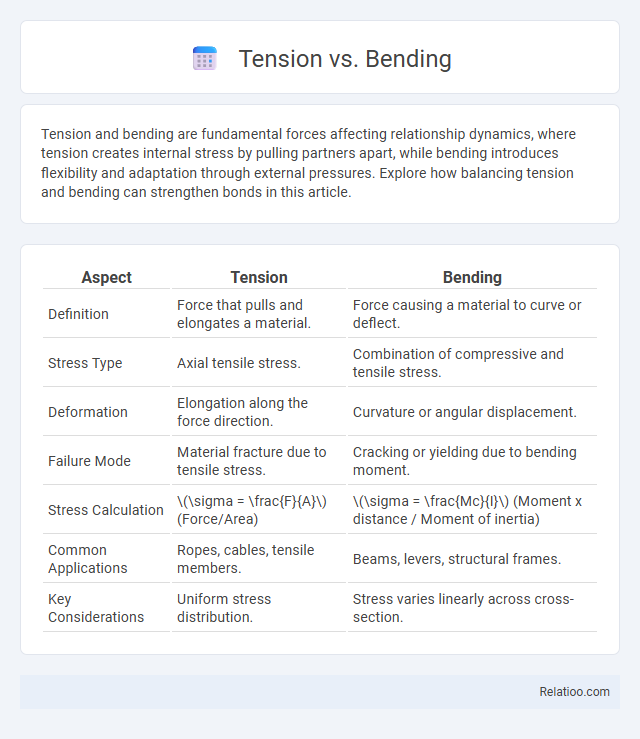

| Aspect | Tension | Bending |

|---|---|---|

| Definition | Force that pulls and elongates a material. | Force causing a material to curve or deflect. |

| Stress Type | Axial tensile stress. | Combination of compressive and tensile stress. |

| Deformation | Elongation along the force direction. | Curvature or angular displacement. |

| Failure Mode | Material fracture due to tensile stress. | Cracking or yielding due to bending moment. |

| Stress Calculation | \(\sigma = \frac{F}{A}\) (Force/Area) | \(\sigma = \frac{Mc}{I}\) (Moment x distance / Moment of inertia) |

| Common Applications | Ropes, cables, tensile members. | Beams, levers, structural frames. |

| Key Considerations | Uniform stress distribution. | Stress varies linearly across cross-section. |

Understanding Tension and Bending Forces

Tension forces pull and stretch materials, causing axial elongation, while bending forces create both tensile and compressive stresses within a structural element due to external loads perpendicular to its length. Understanding tension involves analyzing the uniform distribution of stress along the material's cross-section, whereas bending requires examining stress gradients and neutral axis positions. Engineering designs must account for these fundamental differences to ensure structural integrity and prevent failure under combined loading conditions.

Key Differences Between Tension and Bending

Tension involves forces that stretch a material by pulling it apart, creating uniform axial stress along the length of the object. Bending combines tension and compression stresses, with tension occurring on the convex side and compression on the concave side of the bent material, generating a non-uniform stress distribution. The key difference lies in tension producing purely axial stresses, while bending results in a combination of axial tensile and compressive stresses varying across the cross-section.

How Tension Affects Structural Integrity

Tension directly impacts structural integrity by pulling materials apart, which can cause elongation or failure if the tensile strength is exceeded. Unlike bending, which combines tension and compression, pure tension stresses the entire cross-section uniformly, making your material's tensile properties critical for safety. Properly understanding how tension influences load-bearing components ensures your structure maintains stability and resists deformation under stress.

The Role of Bending in Material Deformation

Bending induces a combination of tensile and compressive stresses across a material's cross-section, leading to deformation that differs from pure tension where stress is uniformly distributed. The outer fibers experience maximum tensile stress while the inner fibers undergo compression, causing curvature and permanent shape change if the material's yield strength is exceeded. Understanding bending's stress distribution is crucial for designing components to withstand complex loading without failure.

Common Applications of Tension in Engineering

Tension is a critical force in engineering, commonly applied in structural elements like cables, tie rods, and suspension bridges, where materials are stretched to resist pulling forces. Unlike bending, which involves both tension and compression within a component, tension exclusively deals with forces that elongate the material, making it essential in applications such as elevator cables, tensile fabric structures, and guy wires for towers. Understanding how tension works in your designs ensures components maintain integrity under loads, enhancing safety and durability in engineering projects.

Bending Forces in Everyday Structures

Bending forces occur when an external load is applied perpendicular to the length of a structural element, causing it to bend and develop tensile and compressive stresses on opposite sides. Everyday structures such as beams in bridges, floors in buildings, and even furniture like chairs endure bending forces that must be carefully accounted for during design to prevent failure. Understanding the distribution of bending moments and shear forces is crucial for selecting appropriate materials and cross-sectional shapes that resist deformation and maintain structural integrity.

Failure Modes: Tension vs Bending

Tension failure occurs when the material is subjected to axial forces causing it to elongate and eventually fracture due to surpassing its tensile strength. Bending failure involves stresses distributed across the material's cross-section, where tension acts on one side and compression on the other, leading to cracking or yielding at the fibers experiencing maximum tension. Your design must consider these failure modes to ensure structural integrity by selecting materials with appropriate tensile and flexural strengths.

Material Selection for Tension and Bending Loads

Material selection for tension loads prioritizes high tensile strength, ductility, and resistance to elongation to prevent failure under pulling forces. For bending loads, materials must exhibit excellent flexural strength, stiffness, and toughness to withstand both tensile and compressive stresses within the bend zone. Your choice should balance these properties based on the dominant load type to ensure structural integrity and longevity.

Design Strategies to Withstand Tension and Bending

Design strategies to withstand tension and bending prioritize material selection with high tensile strength and modulus of elasticity to resist deformation. Optimizing cross-sectional geometry, such as I-beams or box sections, enhances load distribution, minimizing stress concentrations under combined tension and bending forces. You should also incorporate safety factors and conduct finite element analysis to ensure structural integrity under dynamic loading conditions.

Real-World Examples: Tension vs Bending in Action

Tension occurs when forces pull a material apart, such as in suspension bridges where cables carry heavy loads by resisting tensile stress. Bending arises when an external force causes a material to curve or flex, evident in beams supporting floors or the bending of tree branches under wind pressure. Real-world applications demonstrate tension in elevator cables and bending in cantilevered balconies, highlighting how different structural elements resist specific mechanical stresses.

Infographic: Tension vs Bending

relatioo.com

relatioo.com