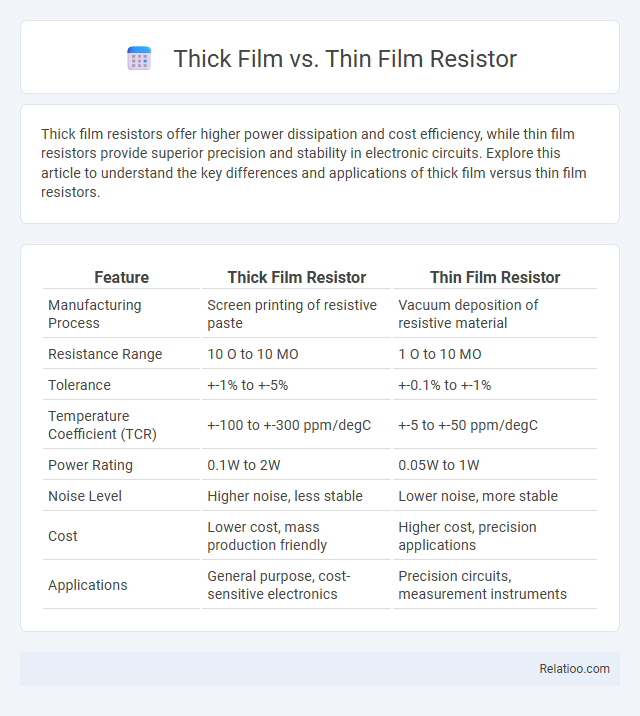

Thick film resistors offer higher power dissipation and cost efficiency, while thin film resistors provide superior precision and stability in electronic circuits. Explore this article to understand the key differences and applications of thick film versus thin film resistors.

Table of Comparison

| Feature | Thick Film Resistor | Thin Film Resistor |

|---|---|---|

| Manufacturing Process | Screen printing of resistive paste | Vacuum deposition of resistive material |

| Resistance Range | 10 O to 10 MO | 1 O to 10 MO |

| Tolerance | +-1% to +-5% | +-0.1% to +-1% |

| Temperature Coefficient (TCR) | +-100 to +-300 ppm/degC | +-5 to +-50 ppm/degC |

| Power Rating | 0.1W to 2W | 0.05W to 1W |

| Noise Level | Higher noise, less stable | Lower noise, more stable |

| Cost | Lower cost, mass production friendly | Higher cost, precision applications |

| Applications | General purpose, cost-sensitive electronics | Precision circuits, measurement instruments |

Introduction to Thick Film and Thin Film Resistors

Thick film resistors feature a layer of resistive paste applied and fired onto a ceramic substrate, offering cost-effective solutions with high power dissipation and stability ideal for general electronic circuits. Thin film resistors use a sputtered metal alloy deposited on an insulating substrate, providing precise resistance values, low noise, and excellent temperature coefficients crucial for high-frequency and precision applications. Understanding your choice between thick film and thin film resistors enables optimized circuit performance by balancing cost, accuracy, and environmental stability.

Understanding the Basics: Construction and Materials

Thick film resistors are made by depositing a paste of conductive material onto a ceramic substrate, offering cost-effective and versatile solutions for high-volume production. Thin film resistors use a sputtering process to apply a thin metal layer on an insulating base, resulting in higher precision and stability essential for sensitive electronic circuits. Understanding these fundamental differences enables you to select the appropriate resistor type based on required performance, reliability, and application-specific needs.

Manufacturing Processes: Thick Film vs Thin Film

Thick film resistors are manufactured by screen-printing a paste containing resistive materials onto a ceramic substrate followed by firing at high temperatures, which results in a robust and cost-effective component ideal for high-volume production. Thin film resistors utilize a vacuum deposition process such as sputtering or evaporation to apply a very thin layer of resistive material on an insulating substrate, offering superior precision, stability, and low noise compared to thick film resistors. Understanding these manufacturing differences helps you select the resistor type best suited for your application requirements based on tolerance, performance, and cost considerations.

Electrical Performance Comparison

Thick film resistors offer higher power ratings and better thermal stability but exhibit greater noise and tolerance variations compared to thin film resistors, which provide superior precision, lower noise, and improved frequency response due to their fine film layers. Thin film resistors maintain tighter resistance tolerances and lower temperature coefficients, making them ideal for applications demanding high accuracy and stability in your circuits. Standard carbon or metal oxide resistors generally have lower performance metrics in terms of noise, tolerance, and stability, impacting overall electrical performance in sensitive electronic designs.

Key Applications in Electronics

Thick film resistors are widely used in power regulation and general-purpose electronics due to their cost-effectiveness and durability under high voltage conditions, while thin film resistors excel in precision circuits, including instrumentation and communication devices, where stability and low noise are critical. Your choice depends on the required tolerance, temperature coefficient, and frequency response; thick film suits harsh environments and higher power dissipation, whereas thin film is preferable for high-frequency and high-precision applications. Standard resistors provide foundational resistance in almost all electronic circuits but are often surpassed by thick and thin film variants when specific performance characteristics are needed in specialized electronic systems.

Tolerance and Precision Differences

Thick film resistors typically have tolerance ranges of +-1% to +-5%, offering moderate precision suitable for general electronic applications. Thin film resistors provide tighter tolerance, often as low as +-0.1%, enabling higher precision for sensitive circuits requiring stable and accurate resistance values. Compared to standard resistors, thin film technology ensures superior temperature coefficient stability and lower noise, making it ideal for high-performance and precision measurement devices.

Cost Analysis and Economic Considerations

Thick film resistors generally offer a lower cost solution for high-volume manufacturing due to their simpler production process and suitability for standard applications, while thin film resistors incur higher costs because of their precise, high-performance characteristics ideal for sensitive electronic equipment. Traditional resistors, often carbon composition or wirewound types, may present cost advantages in specific scenarios but lack the consistency and miniaturization benefits of thick and thin film technologies. Economic considerations must weigh factors such as required tolerance, power rating, and production scale to determine the most cost-effective resistor type for a given application.

Advantages and Disadvantages Overview

Thick film resistors offer cost-effective, high power ratings with good stability, making them ideal for general-purpose applications, while thin film resistors provide superior precision, low noise, and tight tolerance suitable for high-frequency circuits. Your choice depends on performance needs: thick film resistors tend to have higher temperature coefficients and noise levels, whereas thin film resistors offer better accuracy but come at a higher cost and lower power handling. Standard resistors vary widely in types, but selecting between thick film and thin film focuses on balancing durability, precision, and budget constraints.

Environmental and Reliability Factors

Thick film resistors offer improved environmental resistance with better tolerance to moisture and temperature variations compared to thin film resistors, which excel in precision but are more susceptible to mechanical stress and corrosion. Your choice depends on the application's reliability requirements, as thick film resistors are ideal for harsh conditions while thin film resistors provide superior stability in controlled environments. Standard resistors vary widely in materials and construction, affecting their performance and durability under different environmental stresses.

Choosing the Right Resistor for Your Project

Thick film resistors offer cost-effective and reliable solutions with moderate precision, making them ideal for general-purpose electronics and high-volume production. Thin film resistors provide superior accuracy, stability, and low noise, suited for applications requiring high precision such as instrumentation and medical devices. Choosing the right resistor for your project depends on balancing factors like tolerance, power rating, size, and environmental stability to ensure optimal performance and longevity.

Infographic: Thick Film vs Thin Film resistor

relatioo.com

relatioo.com