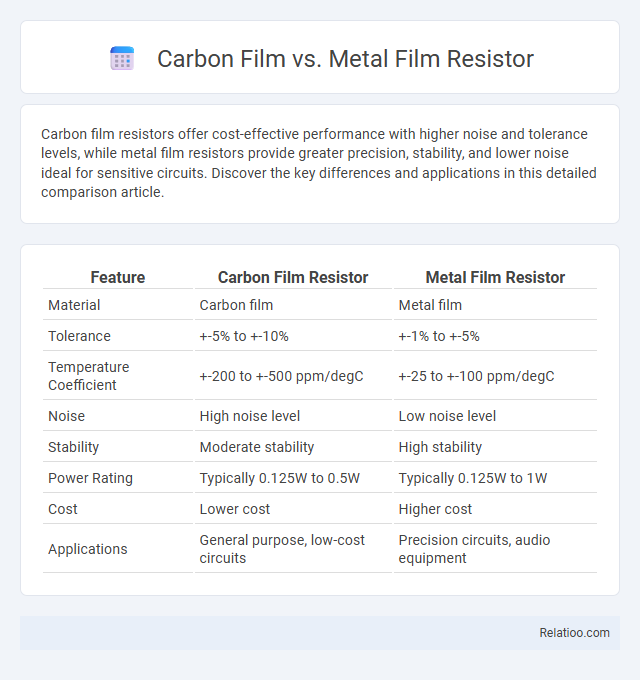

Carbon film resistors offer cost-effective performance with higher noise and tolerance levels, while metal film resistors provide greater precision, stability, and lower noise ideal for sensitive circuits. Discover the key differences and applications in this detailed comparison article.

Table of Comparison

| Feature | Carbon Film Resistor | Metal Film Resistor |

|---|---|---|

| Material | Carbon film | Metal film |

| Tolerance | +-5% to +-10% | +-1% to +-5% |

| Temperature Coefficient | +-200 to +-500 ppm/degC | +-25 to +-100 ppm/degC |

| Noise | High noise level | Low noise level |

| Stability | Moderate stability | High stability |

| Power Rating | Typically 0.125W to 0.5W | Typically 0.125W to 1W |

| Cost | Lower cost | Higher cost |

| Applications | General purpose, low-cost circuits | Precision circuits, audio equipment |

Introduction to Carbon Film and Metal Film Resistors

Carbon film resistors are made by depositing a thin layer of carbon onto an insulating substrate, offering stable resistance values with moderate noise levels and cost-effectiveness. Metal film resistors, consisting of a thin metal alloy film, provide superior precision, lower noise, and better temperature stability compared to carbon film resistors. Both types are widely used in electronic circuits, with metal film resistors preferred for high-accuracy applications and carbon film resistors favored for general-purpose use.

Material Composition and Structure

Carbon film resistors use a thin layer of carbon deposited on an insulating substrate, providing moderate stability and noise performance, while metal film resistors employ a thin metallic alloy film offering higher precision, lower noise, and better temperature stability. Carbon composition resistors consist of a homogeneous mixture of carbon particles and ceramic binder, resulting in higher noise and wider tolerance compared to film resistors. Metal film resistors feature a tightly controlled spiral or helical deposition of metal on ceramic cores, enabling superior accuracy and consistent resistance values in electronic circuits.

Manufacturing Process Comparison

Carbon film resistors are manufactured by depositing a thin layer of carbon on an insulating substrate, followed by laser trimming to achieve precise resistance values, resulting in moderate tolerance and noise levels. Metal film resistors use a similar process but deposit a thin metal alloy film, offering higher stability, lower noise, and tighter tolerance due to superior material uniformity and controlled evaporation techniques. While both rely on film deposition and trimming, metal film manufacturing involves more precise control over film thickness and composition, leading to enhanced performance compared to carbon film.

Electrical Performance Characteristics

Carbon film resistors typically exhibit higher noise levels and less precision compared to metal film resistors, which provide superior stability, lower noise, and tighter tolerance values, making them ideal for high-accuracy applications. Metal film resistors often feature better temperature coefficients and long-term reliability due to their uniform film deposition, whereas carbon film resistors may experience greater drift under temperature variations and aging. When selecting a resistor for Your circuit's electrical performance, consider metal film resistors for enhanced precision, noise reduction, and stability, especially in sensitive analog or measurement applications.

Tolerance and Precision Differences

Metal film resistors generally offer tighter tolerance levels, commonly around +-1% or lower, making them more precise compared to carbon film resistors, which typically have tolerances of +-5% or higher. The improved precision of metal film resistors is due to their uniform construction and stable materials, resulting in lower noise and temperature coefficients. Carbon film resistors, while cost-effective, exhibit greater variance in resistance values and higher noise, limiting their use in applications demanding high accuracy and stability.

Temperature Coefficient Analysis

Carbon film resistors exhibit higher temperature coefficients, typically around +-200 to +-500 ppm/degC, causing greater resistance variation with temperature changes. Metal film resistors offer significantly improved stability, with temperature coefficients as low as +-5 to +-50 ppm/degC, ensuring minimal resistance fluctuation and enhanced precision in demanding applications. Standard resistors with unspecified materials often have wider temperature coefficient ranges, making metal film resistors preferable for temperature-sensitive circuits requiring high accuracy.

Noise Generation and Stability

Metal film resistors exhibit lower noise generation compared to carbon film resistors due to their uniform metal oxide layer, which reduces irregularities and excess noise. Carbon film resistors tend to produce higher excess noise because of their graphite composition, making them less stable in precision circuits. Metal film resistors also offer superior long-term stability and temperature coefficient performance, enhancing circuit reliability in sensitive electronic applications.

Typical Applications in Electronics

Carbon film resistors are commonly used in general-purpose electronic circuits such as audio equipment and consumer electronics due to their cost-effectiveness and moderate tolerance levels. Metal film resistors provide higher precision and stability, making them ideal for applications requiring low noise and high accuracy, such as instrumentation and medical devices. Your choice depends on whether you prioritize affordability with adequate performance or precision and reliability in critical electronic applications.

Cost and Availability Considerations

Carbon film resistors generally offer lower cost due to simpler manufacturing processes and wide availability for standard resistance values, making them suitable for budget-sensitive projects. Metal film resistors provide higher precision and stability at a slightly increased price and may be less ubiquitous in ultra-low-cost or high-wattage applications. Overall, carbon film resistors dominate in cost-effectiveness and readily available stock, while metal film resistors balance moderate cost with enhanced performance and are common in precision electronics markets.

Selecting the Right Resistor for Your Project

When selecting the right resistor for your project, consider the differences between carbon film and metal film resistors, as well as generic resistors. Carbon film resistors offer cost-effective solutions with moderate noise levels and stability, making them suitable for general-purpose circuits. Metal film resistors provide superior precision, low noise, and excellent temperature stability, ideal for high-accuracy and low-noise applications.

Infographic: Carbon Film vs Metal Film resistor

relatioo.com

relatioo.com