Tension in relationships is the emotional stress caused by unresolved conflicts, while strain refers to the cumulative pressure that weakens the bond over time. Explore how managing tension and reducing strain can strengthen your relationship in this article.

Table of Comparison

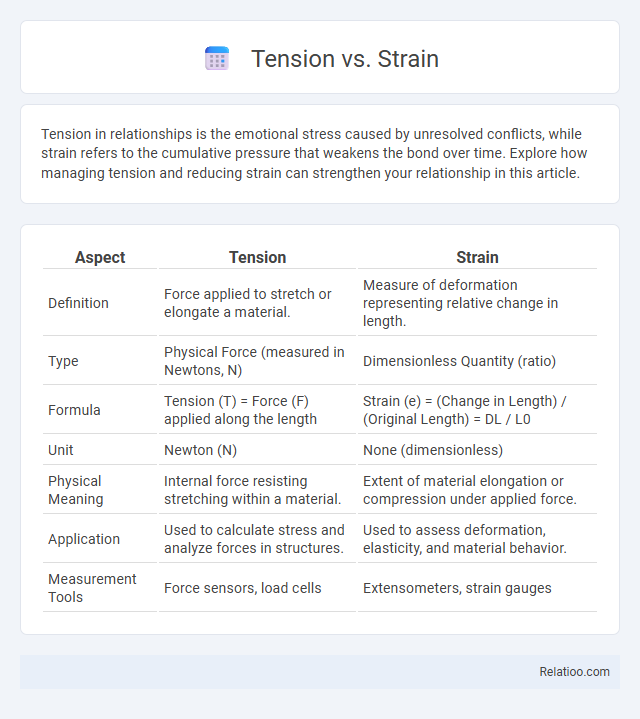

| Aspect | Tension | Strain |

|---|---|---|

| Definition | Force applied to stretch or elongate a material. | Measure of deformation representing relative change in length. |

| Type | Physical Force (measured in Newtons, N) | Dimensionless Quantity (ratio) |

| Formula | Tension (T) = Force (F) applied along the length | Strain (e) = (Change in Length) / (Original Length) = DL / L0 |

| Unit | Newton (N) | None (dimensionless) |

| Physical Meaning | Internal force resisting stretching within a material. | Extent of material elongation or compression under applied force. |

| Application | Used to calculate stress and analyze forces in structures. | Used to assess deformation, elasticity, and material behavior. |

| Measurement Tools | Force sensors, load cells | Extensometers, strain gauges |

Understanding Tension and Strain: Key Concepts

Tension refers to the force exerted along a material that stretches it, while strain measures the resulting deformation or elongation relative to the material's original length. Understanding tension and strain is crucial for analyzing how materials respond under load, ensuring your structural designs maintain integrity and performance. Accurate evaluation of these concepts helps predict material behavior, prevent failure, and optimize engineering solutions.

Fundamental Differences Between Tension and Strain

Tension is the force applied to a material causing it to stretch, measured in units like newtons or pounds-force, while strain is the resulting deformation or change in length relative to the original length, expressed as a dimensionless ratio or percentage. Your understanding of the fundamental differences between tension and strain is crucial for analyzing material behavior under load, as tension concerns the applied force and strain describes the material's response. Engineers use these distinct yet interrelated concepts to predict failure points and ensure structural integrity in various applications.

The Science Behind Tension in Materials

Tension refers to the force applied to a material that attempts to stretch it, causing internal stress measured in pascals (Pa). Strain quantifies the deformation or elongation resulting from this applied tension, expressed as a dimensionless ratio of change in length to original length. Understanding the science behind tension helps you predict material behavior under loads, ensuring structural integrity and performance in engineering applications.

Exploring Strain: Definitions and Types

Strain represents the deformation experienced by a material when subjected to stress, measured as the ratio of change in length to original length. Your understanding of strain includes elastic strain, which is reversible, and plastic strain, which causes permanent deformation. Differentiating strain types is crucial for predicting material behavior under tension and ensuring structural integrity.

Tension vs Strain: How They Interact

Tension refers to the force applied to a material, causing it to stretch, while strain measures the material's deformation relative to its original length. The interaction between tension and strain is fundamental in material science, where stress-strain curves illustrate how materials respond under varying loads. Understanding this relationship enables accurate predictions of material behavior under tensile forces, essential for engineering applications.

Real-World Applications of Tension and Strain

Tension and strain are crucial in real-world applications, especially in engineering and materials science, where tension refers to the force applied to an object, and strain measures its deformation under that force. Understanding how materials respond to tension and strain helps you design structures and products that resist breaking or deforming under stress, such as bridges, aircraft wings, and tensile cables. Accurate assessment of these properties ensures safety, durability, and performance across various industries.

Mathematical Formulas for Measuring Tension and Strain

Tension is calculated using the formula \( T = F / A \), where \( T \) represents tension (stress), \( F \) is the applied force, and \( A \) is the cross-sectional area. Strain is measured as the ratio of change in length to the original length, expressed mathematically as \( \varepsilon = \Delta L / L_0 \). Both tension and strain equations are fundamental in understanding material deformation and mechanical properties.

Common Misconceptions About Tension and Strain

Tension and strain are often confused, but tension refers to the force applied to a material while strain measures the deformation resulting from that force. A common misconception is believing tension and strain are interchangeable, when tension is a cause and strain is the effect. Understanding this distinction helps you accurately analyze material behavior under stress for precise engineering applications.

Factors Influencing Tension and Strain in Structures

Tension and strain in structures are influenced by factors such as material properties, cross-sectional area, and external forces applied. Your understanding of how load magnitude, temperature changes, and structural geometry affect tension and strain is crucial for accurate stress analysis. These variables determine the deformation and potential failure points within structural components under varying operational conditions.

Importance of Tension and Strain in Engineering

Tension and strain are fundamental concepts in engineering that describe how materials respond to forces and deformations, directly impacting structural integrity and safety. Tension refers to the force applied to stretch a material, while strain measures the resulting deformation relative to its original length. Understanding the relationship between tension and strain helps engineers design materials and structures that can withstand operational stresses, ensuring durability and preventing failure.

Infographic: Tension vs Strain

relatioo.com

relatioo.com