Surface-Mount Device (SMD) resistors offer compact size and superior performance for high-frequency applications compared to traditional Through Hole resistors, which are preferred for their robustness and ease of manual assembly. Discover the detailed advantages and application scenarios of SMD versus Through Hole resistors in this article.

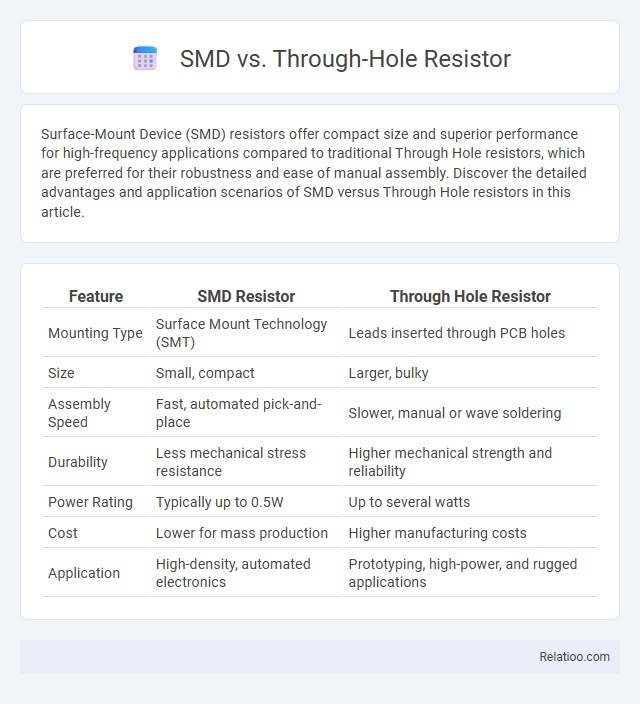

Table of Comparison

| Feature | SMD Resistor | Through Hole Resistor |

|---|---|---|

| Mounting Type | Surface Mount Technology (SMT) | Leads inserted through PCB holes |

| Size | Small, compact | Larger, bulky |

| Assembly Speed | Fast, automated pick-and-place | Slower, manual or wave soldering |

| Durability | Less mechanical stress resistance | Higher mechanical strength and reliability |

| Power Rating | Typically up to 0.5W | Up to several watts |

| Cost | Lower for mass production | Higher manufacturing costs |

| Application | High-density, automated electronics | Prototyping, high-power, and rugged applications |

Introduction to SMD and Through Hole Resistors

Surface-mount device (SMD) resistors are compact, lightweight components designed for automated placement on printed circuit boards (PCBs), enhancing circuit density and performance in modern electronics. Through hole resistors feature wire leads that pass through drilled holes in the PCB, providing strong mechanical bonds suitable for high-stress environments and easier manual assembly. Selection between SMD and through hole resistors depends on factors like space constraints, manufacturing processes, and application-specific durability requirements.

Construction and Design Differences

Surface Mount Device (SMD) resistors feature a compact, rectangular ceramic substrate with resistive film layers deposited on their surface, designed for automatic placement on PCBs, which contrasts with the cylindrical, wire-leaded construction of through-hole resistors that allow for hand soldering and mechanical stability. Through-hole resistors have a resistive wire or film wrapped around a ceramic core with axial leads, providing higher power dissipation and robustness in environments with mechanical stress, while SMD resistors prioritize space-saving, lower inductance, and high-frequency performance. The design differences affect thermal management, with through-hole resistors having better heat dissipation due to their larger size and leads acting as heat sinks, whereas SMD resistors rely on PCB pads for heat sinking but enable higher component density in modern electronic assemblies.

Advantages of SMD Resistors

SMD resistors offer significant advantages over through-hole resistors, including smaller size, allowing for higher component density and more compact circuit designs. Their surface-mount technology supports automated assembly, leading to faster production and lower manufacturing costs. You benefit from improved performance in high-frequency applications due to reduced parasitic inductance and capacitance in SMD resistors.

Benefits of Through Hole Resistors

Through hole resistors offer superior mechanical stability and higher power dissipation capabilities compared to SMD resistors, making them ideal for applications requiring robust performance in harsh environments. Their larger size facilitates easier manual soldering and inspection, which benefits prototyping and repair processes. Through hole technology also supports components with higher voltage ratings, enhancing reliability in high-stress electrical circuits.

Size and Space Considerations

SMD resistors are significantly smaller than through-hole resistors, making them ideal for compact PCB designs where space savings are critical. Through-hole resistors require more board area and hole placements, which can limit component density and complicate automated assembly processes. The choice between SMD and through-hole resistors directly impacts the overall size, weight, and layout efficiency of electronic circuits.

Performance and Reliability Comparison

SMD resistors offer superior high-frequency performance and lower parasitic inductance compared to through-hole resistors, making them ideal for modern compact electronic circuits. Through-hole resistors provide robust mechanical strength and better heat dissipation, enhancing reliability in high-stress or high-power applications. Your selection should balance performance needs with environmental durability to ensure long-term circuit stability.

Manufacturing and Assembly Processes

Surface-mount device (SMD) resistors enable automated pick-and-place assembly, significantly increasing production speed and reducing labor costs compared to traditional through-hole resistors, which require manual insertion and wave soldering. Through-hole resistors provide stronger mechanical bonds, making them ideal for prototypes and applications subject to mechanical stress, but their assembly process is slower and more labor-intensive. The choice between SMD and through-hole resistors impacts manufacturing efficiency, assembly line throughput, and overall production cost due to differences in soldering techniques and component handling.

Cost Analysis: SMD vs Through Hole

Surface Mount Device (SMD) resistors offer significant cost advantages over Through Hole resistors due to automated assembly processes reducing labor expenses and increasing production speed. While Through Hole resistors generally incur higher costs from manual insertion and complex machining requirements, their robustness suits prototypes and low-volume applications where durability is critical. Economies of scale further decrease the cost per unit for SMD resistors in mass manufacturing, making them the preferred choice for cost-effective, high-volume electronic production.

Common Applications and Use Cases

SMD resistors are ideal for compact, high-density circuit boards in devices like smartphones and laptops due to their small size and automated assembly compatibility. Through hole resistors excel in applications requiring enhanced durability and heat dissipation, such as power supplies and industrial equipment. Your choice between these resistor types depends on the specific requirements of your electronic project, including size constraints, mechanical strength, and environmental conditions.

Choosing the Right Resistor for Your Project

Selecting the right resistor involves comparing Surface-Mount Device (SMD) resistors and Through-Hole resistors based on your project's size, power requirements, and assembly process. SMD resistors offer compact size and superior performance at high frequencies, ideal for modern, densely packed circuit boards, while Through-Hole resistors provide ease of manual assembly and greater mechanical strength, suitable for prototyping or high-power applications. Understanding your project's electrical specifications and manufacturing constraints will guide you to choose a resistor that optimizes reliability and efficiency.

Infographic: SMD vs Through Hole resistor

relatioo.com

relatioo.com