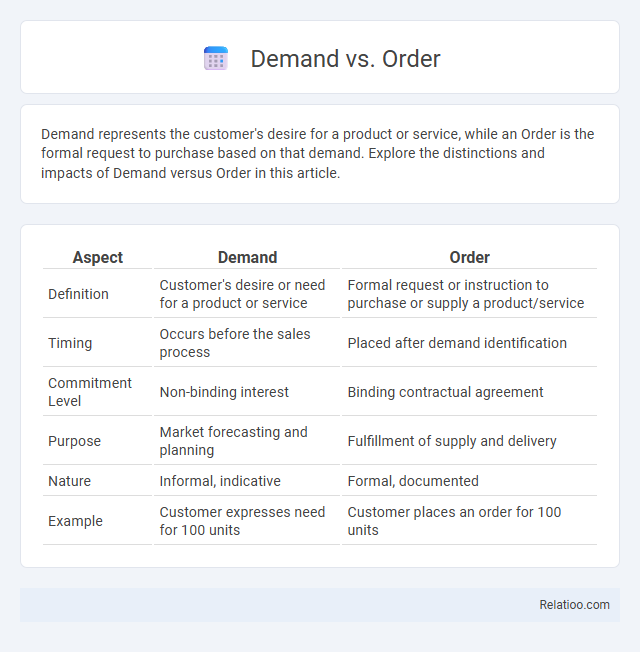

Demand represents the customer's desire for a product or service, while an Order is the formal request to purchase based on that demand. Explore the distinctions and impacts of Demand versus Order in this article.

Table of Comparison

| Aspect | Demand | Order |

|---|---|---|

| Definition | Customer's desire or need for a product or service | Formal request or instruction to purchase or supply a product/service |

| Timing | Occurs before the sales process | Placed after demand identification |

| Commitment Level | Non-binding interest | Binding contractual agreement |

| Purpose | Market forecasting and planning | Fulfillment of supply and delivery |

| Nature | Informal, indicative | Formal, documented |

| Example | Customer expresses need for 100 units | Customer places an order for 100 units |

Understanding Demand in Business

Understanding demand in business entails recognizing the quantity of goods or services consumers are willing and able to purchase at various price levels. Unlike orders, which represent actual customer requests for products, demand reflects potential market desire and purchasing power that drive sales forecasts and inventory management. You can leverage accurate demand analysis to optimize production, align supply chains, and improve overall profitability.

Defining Orders in the Supply Chain

Orders in the supply chain refer to specific requests placed by customers or retailers to procure products or services, serving as the actionable step following demand identification. Your ability to distinguish orders from demand enables accurate inventory management and efficient fulfillment processes, ensuring timely delivery and customer satisfaction. Understanding that demand represents the market desire, while orders are concrete commitments, is crucial for optimizing supply chain operations.

Key Differences Between Demand and Order

Demand represents the consumer's desire and willingness to purchase goods or services, influenced by factors like price and income, while an order is the formal request placed by the consumer to buy a specific quantity of a product or service. Demand is an abstract economic concept reflecting market needs, whereas an order is a concrete transaction step that initiates the supply chain process. Understanding this difference helps ensure Your business accurately forecasts market trends and responds promptly to actual customer purchases.

The Role of Demand Forecasting

Demand forecasting plays a critical role in distinguishing between demand, orders, and overall supply chain management by predicting future customer demand using historical sales data, market trends, and statistical models. Accurate demand forecasts enable businesses to optimize inventory levels, reduce stockouts, and align production schedules with expected order volume. Effective demand forecasting improves order fulfillment rates and minimizes excess inventory costs, directly impacting operational efficiency and customer satisfaction.

Order Management Processes Explained

Order management processes involve tracking and managing customer orders from initiation to fulfillment, ensuring timely delivery and accurate inventory control. Demand refers to the customer's need or desire for products, which drives order generation but does not guarantee an immediate transaction. Understanding the distinction between demand, order, and supply helps your business optimize inventory levels and streamline the entire order lifecycle for improved customer satisfaction.

How Demand Influences Orders

Demand directly impacts orders by driving the quantity and frequency customers are willing to purchase your products or services. As demand increases, orders typically grow in volume, prompting businesses to adjust inventory, production, and supply chain management accordingly. Understanding your customer's demand patterns helps optimize order fulfillment, reduce stockouts, and improve overall operational efficiency.

Impacts of Overestimating Demand

Overestimating demand can lead to excess inventory, increased holding costs, and tied-up capital that could otherwise be used for growth initiatives. Your supply chain efficiency may suffer as overproduction causes bottlenecks and resource wastage, ultimately reducing profitability. Accurate demand forecasting is crucial to balance order quantities and minimize financial risks associated with surplus products.

Aligning Orders with Market Demand

Aligning orders with market demand ensures inventory levels accurately reflect customer needs, minimizing stockouts and overstock situations. Effective demand forecasting uses historical sales data, market trends, and customer behavior insights to synchronize order quantities with anticipated sales. This alignment enhances supply chain efficiency, reduces carrying costs, and improves customer satisfaction by delivering products promptly.

Common Challenges in Demand and Order Management

Demand and order management both face challenges such as inaccurate demand forecasting, leading to stockouts or excess inventory. Integrating real-time data from multiple sales channels remains difficult, causing delays in order fulfillment and reduced customer satisfaction. Inefficient communication between supply chain stakeholders often results in misaligned objectives and operational inefficiencies.

Strategies to Balance Demand and Orders

Balancing demand and orders requires accurate demand forecasting using historical sales data and market trends to align inventory levels with customer needs. Implementing flexible supply chain strategies, such as just-in-time inventory and dynamic order management systems, helps you minimize stockouts and overstock situations. Continuous collaboration with suppliers and real-time data analytics further optimizes order fulfillment and enhances customer satisfaction.

Infographic: Demand vs Order

relatioo.com

relatioo.com